Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

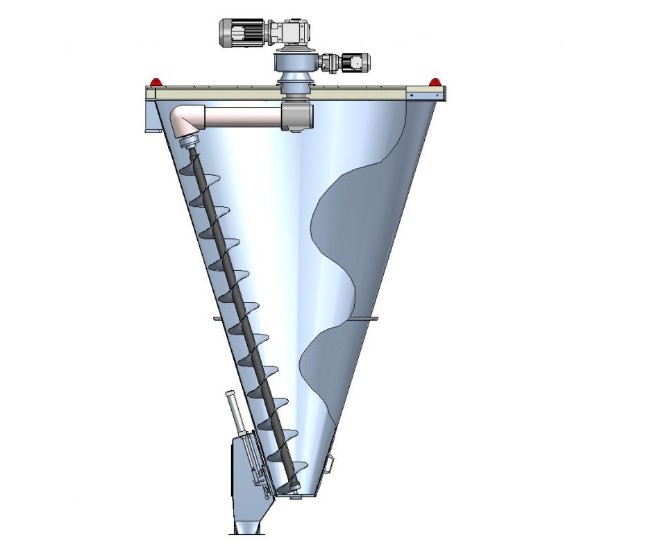

Conical Screw Mixer applied in Dyestuff Industry

Dyestuff is a widely demand industry with more than 100 years history around world and it is a very important part of chemical industry. It makes our world to be colorful and people highly reply on dyes. Due to the important position of dyestuff, more efficient production is necessary to every dyestuff manufacturers. With increasing price of dyestuff raw material, more and more manufacturers are being built in these two years in developing countries such as China, India, Bangladesh and etc. When engineer design dyestuff plant, he must take consideration of environment pollution issue, dust collecting issue, more productive and cost saving. However, conical screw mixer plays a key role in the total manufacturing process. And Vortex mixer machine coud be designed to meet customer requirement and help dyestuff manufacturer to lift their business.

At before, many manufacturers prefer horizontal ribbon mixer because of high homogeneity, lower height and Easy Maintenance but the critical disadvantage is many residues because ribbon mixer can not discharge material totally and clean. If manufacturer want to change formulation per shift, it need to be totally cleaned and takes very long time. Now, Vortex conical screw mixer can solve this problem and it has been widely used in dyestuff factories.

Firstly, the capacity of conical screw mixer ranges from 100L to 50000L total volume to meet different production demand. For many batch mixing of final dyestuff products, they need very big capacity mixer. We sold many 20 cubic meters conical screw mixer to Sudarshan Chemical in India.

Secondly, totally discharge and no residues is an obvious advantage compared with horizontal ribbon mixer. Conical shape vessel and bottom discharge valve makes all material come out when open valve. Moreover, discharge speed is also very fast and all material can be discharged within 5 mins.

Thirdly, easy maintenance and clean is also a key part need to be considered. In our conical screw mixer design, the mixing screw and drive arm is flange assembly which can be split if something broken. If worker want to clean inside of mixer, he can load water into mixer and running the machine. It can be cleaned fast.

As for raw material feeding, more and more manufacturers use vacuum feeding system rather than screw feeding because it is clean and efficient. Overall, conical screw mixer is a trend to mix dyestuff and it will replace horizontal ribbon mixer in the future. Vortex will put much effort in developing more friendly conical screw mixer.