Photo Gallery

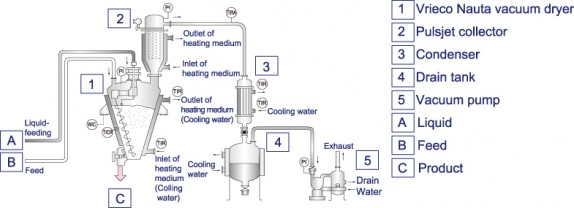

Nauta dryer is a kind of conical vacuum dryer, there is an agitator inside the cylinder to stir the raw material, which could reach GMP standard, is widely used for pharmaceutical, biological, chemical and food industries. And it is suitable for drying and concentrating liquid, filter cake, powder and particle material.

The thermal energy needed for drying is introduced into the product through a heated jacket that can be heated by various media including steam, hot oil and water. The jacket provides rapid distribution of heat into the product in combination with efficient mixing.

The vacuum inside the dryer allows vapor to be removed at low temperatures, which makes the conical screw vacuum dryer ideal for drying heat-sensitive products. The vapors are removed through a dust filter fitted on top of the vessel. This then prevents the dust from penetrating into the vacuum system.

The conical screw vacuum dryer is fitted with a condenser with a receptacle for recovering solvents. This condenser can be installed before the vacuum pump, or after it, depending on the characteristics of the solvents.

The moisture content of the product can be controlled by monitoring the weight of condensate or using the Vortex sampler for taking samples from the product inside the dryer under vacuum.