Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

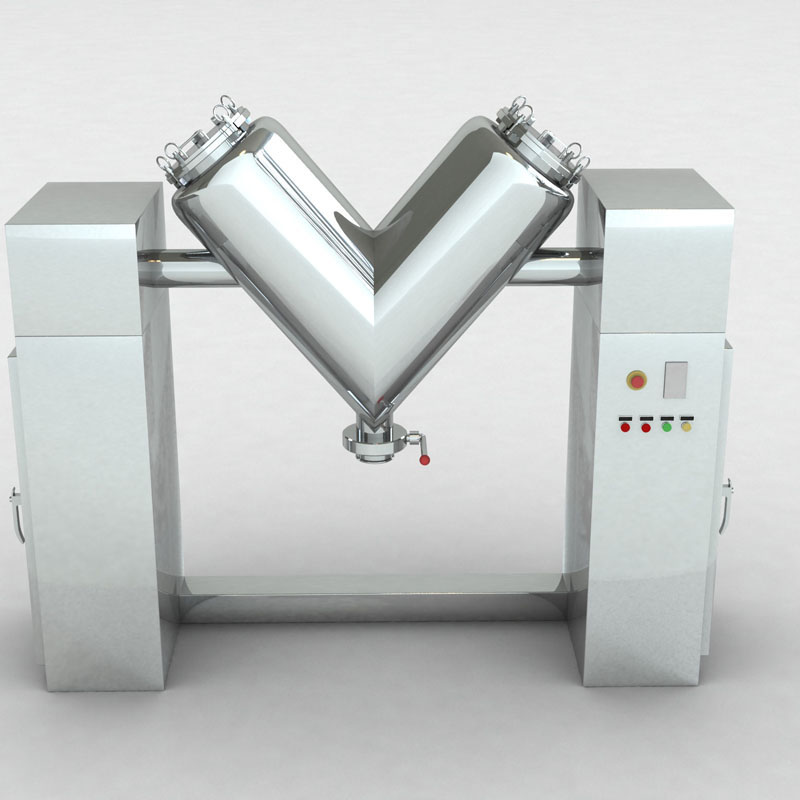

The Safety Features of Vortex V-type Blender

In order to make safer tumble blender, Vortex Mixing Company now introduce brake motor to equip on the tumble blender, such as V-type blender or double cone blender. And the brake motor allows the tumbling V-type blender and double cone blender vessel to safely decelerate to a complete stop at the proper upright position, this feature is very safe and immediately.

Pictured are one 200L V-type tumble blender which designed for mixing raw materials with bulk densities from 0.3 to 1.5 and the working capacity could up to 300kg. Inside the V-type blender, free-flowing solids or powders are gently and intimately blended as the cone vessel rotates. To supplement the low-impact mixing action, a high-speed intensifier bar is supplied for breaking up lumps and agglomerates if necessary. The intensifier bar/chopper could include multiple spray nozzles for adding small quantity liquid ingredients to the blending batch.

As for this V-type blender, all product contact parts are made of stainless steel 304 polished to 240-grit finish for easy discharge of products and cleaning of vessel. The tumbling vessel is driven by a 1.1kw brake motor while the intensifier bar/chopper is driven by a 0.75kw motor. A safety gate around the blender prevents operation of the tumbling vessel when the gate open. The finished products are discharged through a dust-light butterfly valve. The V-type blender featured with completely discharge of products.

As for V-type blender, we are available in many standard sizes from 20L to 5000L, and vortex V-type blender are offered with various options such as vacuum application, heavy-duty design for high-density application, heating and cooling jacket, explosion-proof motor and PLC controls. We also provide technical support from planning and engineering to delivery and stand-up.

For more information, please email us to info@incmachine.com freely at any time.